Optimal tuning

The performance of a biogas lamp is dependent on

optimal tuning of the incandescent body (gas

mantle) and the shape of the flame at the nozzle,

i.e. the incandescent body must be surrounded by

the inner (=hottest) core of the flame at the

minimum gas consumption rate. If the incandescent

body is too large, it will show dark spots; if the flame

is too large, gas consumption will be too high for the

light-flux yield. The lampshade reflects the light

downward, and the glass prevents the loss of heat.

Shortcomings of commercial-type biogas lamps

Practical experience shows that commercial-type

gas lamps are not optimally designed for the

specific conditions of biogas combustion (fluctuating

or low pressure, varying gas composition). The most

frequently observed shortcomings are:

• excessively large nozzle diameters

• excessively large gas mantles

• no possibility of changing the injector

• poor or lacking means of combustion-air

control

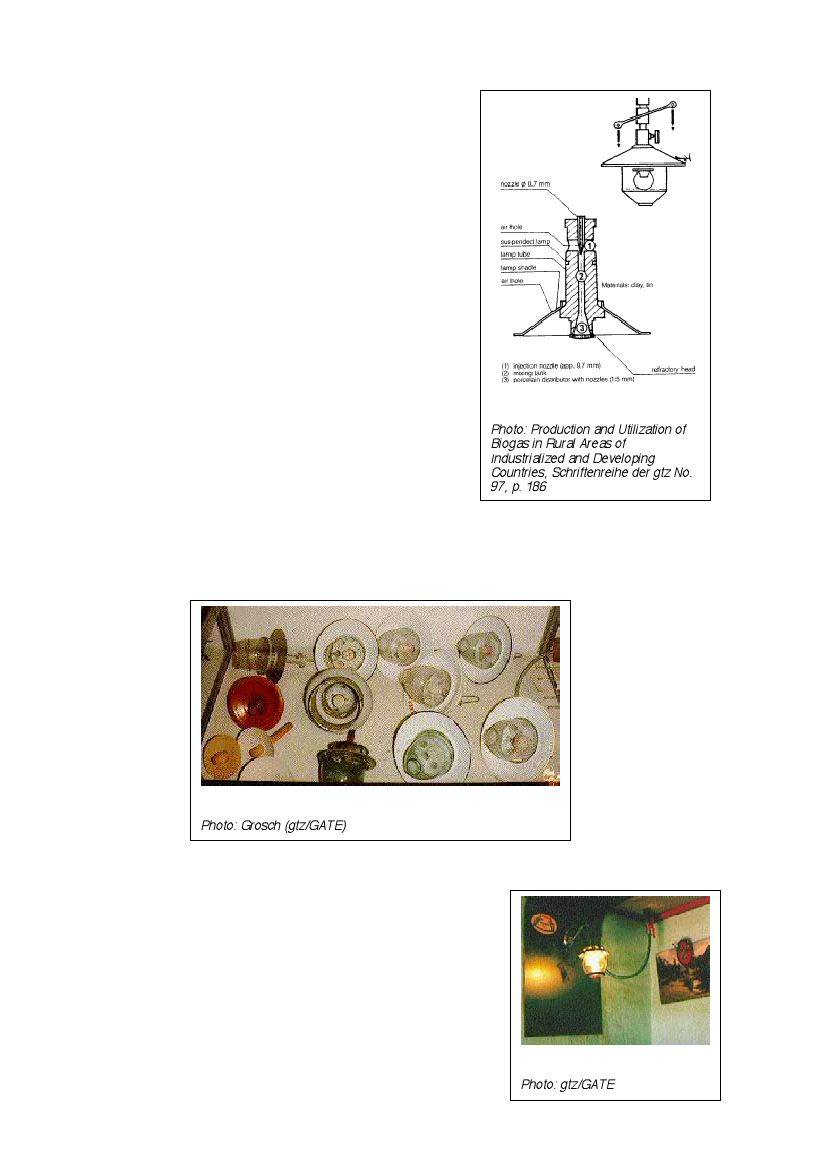

Figure 11: Schematic structure of

a biogas lamp

Photo: Production and Utilization of

Biogas in Rural Areas of

Industrialized and Developing

Countries, Schriftenreihe der gtz No.

97, p. 186

Such drawbacks result in unnecessarily high gas consumption and poor lighting. While the

expert/extension officer has practically no influence on how a given lamp is designed, he can

at least give due consideration to the mentioned aspects when it comes to selecting a

particular model.

Figure 12: Different types of Biogas lamps at an agricultural

exhibition in Beijing/China

Photo: Grosch (gtz/GATE)

Adjusting a biogas lamp

Biogas lamps are controlled by adjusting the supply of

gas and primary air. The aim is to make the gas mantle

burn with uniform brightness and a steady, sputtering

murmur (sound of burning, flowing biogas). To check the

criteria, place the glass on the lamp and wait 2-5 minutes,

until the lamp has reached its normal operating

temperature. Most lamps operate at a gas pressure of 5-

15 cm WC (water column). If the pressure is any lower,

the mantle will not glow, and if the pressure is too high

(fixed-dome plants) the mantle may tear.

Figure 13: Biogas lamp in

Burundi

Photo: gtz/GATE

21